So While I have been waiting to pick up the engine from the shop, I started to polish the intake manifold. I don't know what I was thinking this is a really long process that is no where close to being done. I almost said screw it and just use another upper intake manifold, but I've found out that somehow this car has a 2.9 liter intake manifold from European VR6 engine.

Here is the intake manifold from my red Corrado.

Here is the intake manifold from my '93 Corrado that all the American versions should have had.

Here is the progress on the polishing... Before

And where I'm at with it now...

Tuesday I picked up the engine from

the shop and talked with the owner Tom. He reassured me the bottom end of the engine and the rotating assembly are in great shape and confirmed what little I know about the engine in that it did in fact have a bent valve.

Bringing 'her home.

Thanks to my good friend and neighbor Jerome I was able to get the engine on the stand.

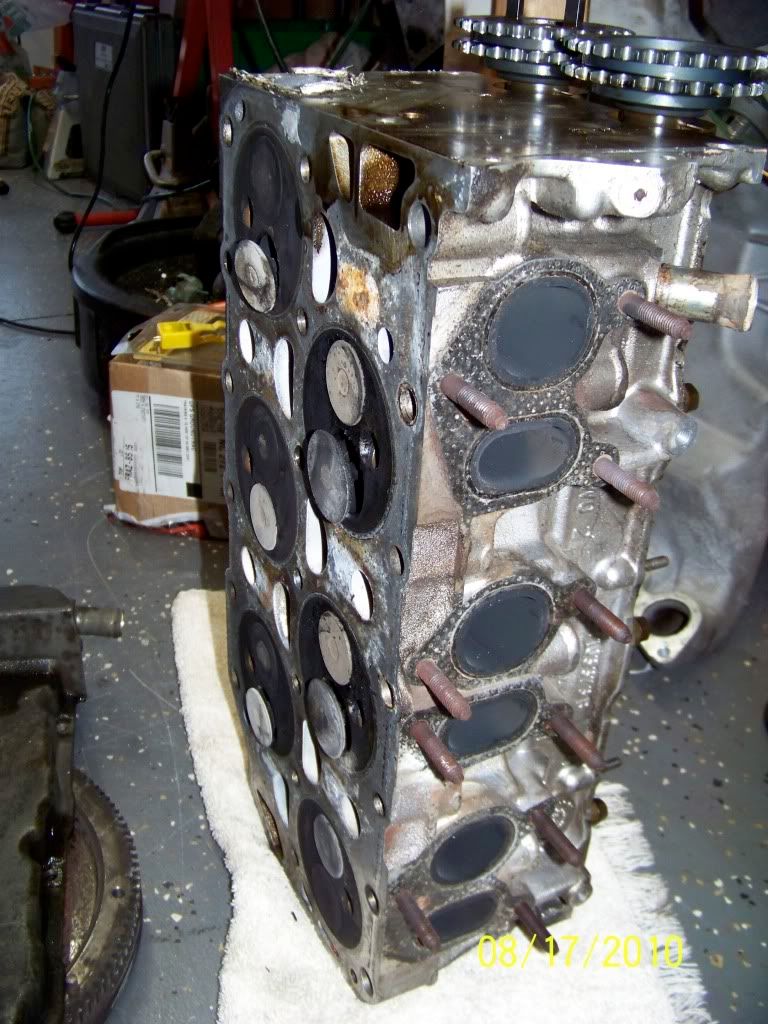

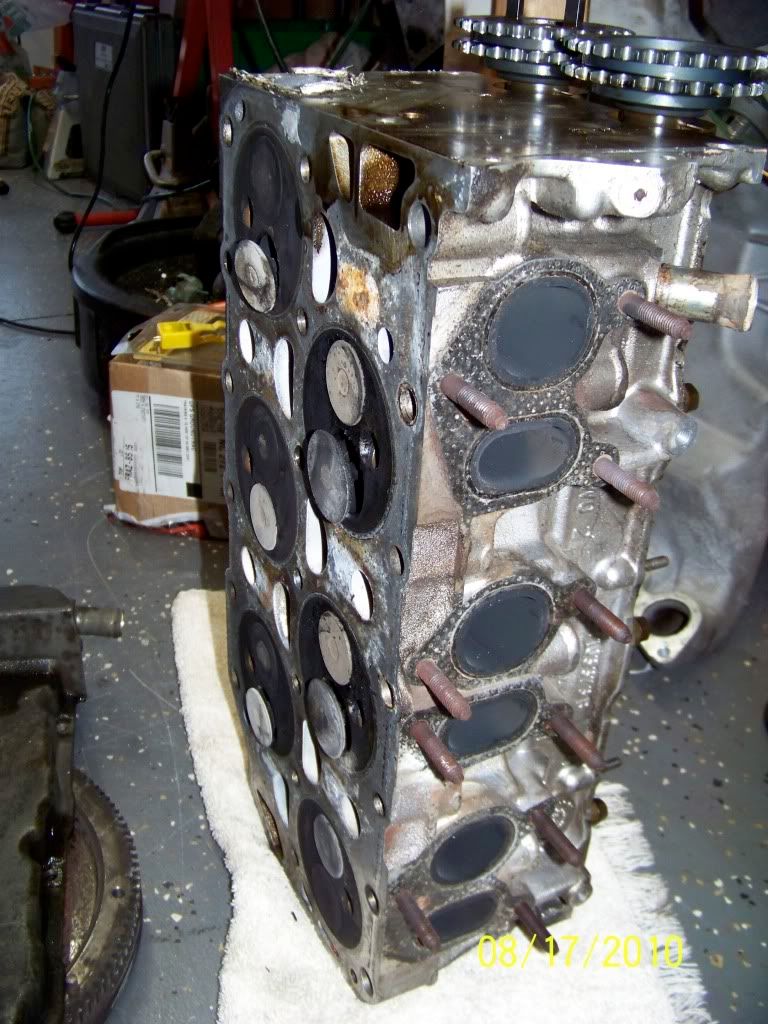

In this picture below you can see the culprit of the bent valves according to Tom. The bolt holding in the upper gear for the timing chain was loose and cause that gear to be loose enough to throw the timing off and valves went crashing into the pistons.

Here's the damage visually, there may be more; I will have to take the head to machine shop and see how it tests. There are at least 4 valves bent that I can see.

As usual more to come...